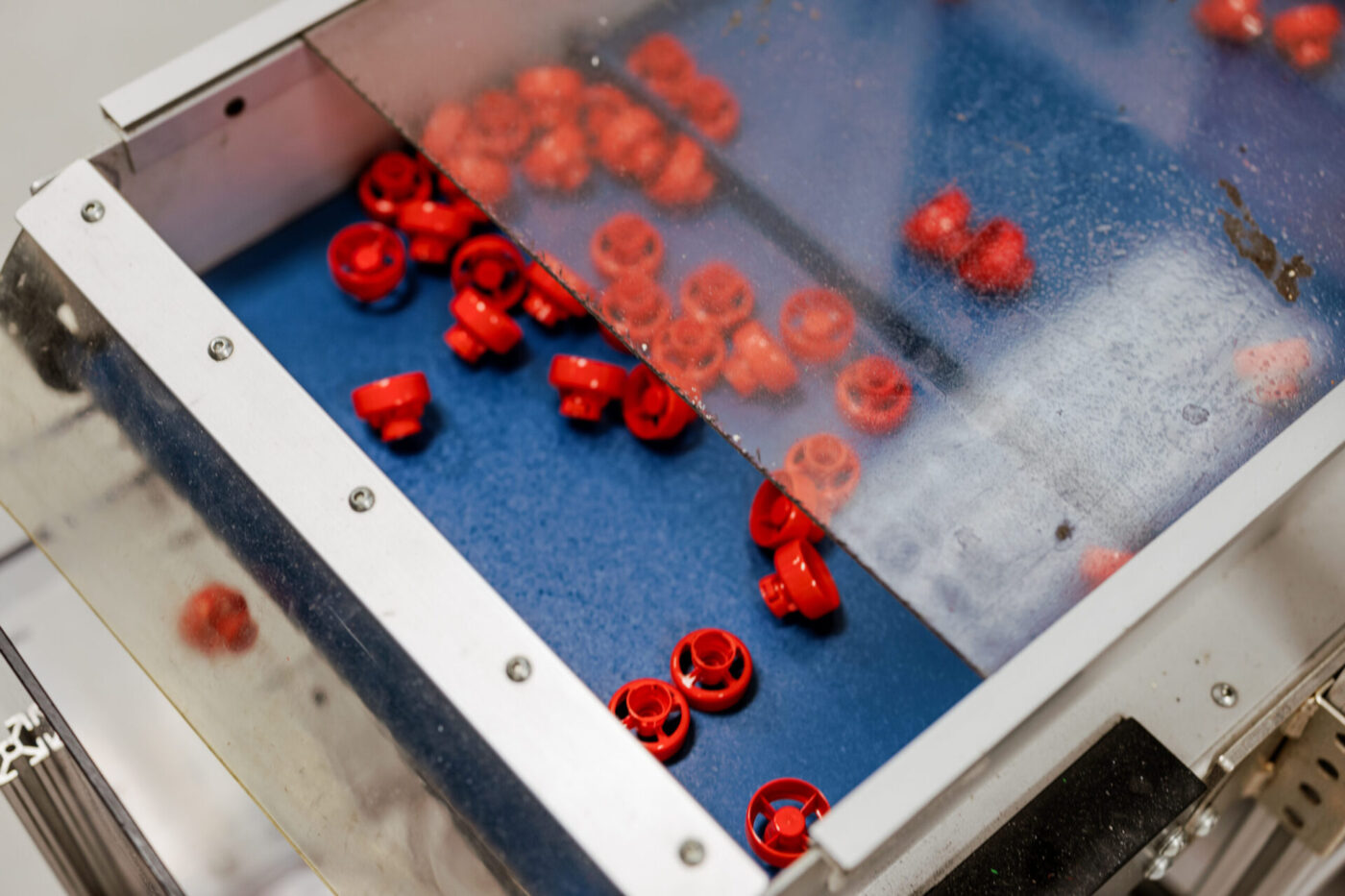

Innovative closures, fitments and dispensing components designed to protect products, enhance usability and communicate brand value.

Hoffer Plastics partners with leading brands and packaging suppliers to deliver injection-molded packaging components that perform reliably and scale globally. Backed by decades of technical expertise and family-owned accountability, we combine engineering insight with manufacturing excellence to help customers reduce risk, advance sustainability and strengthen brand integrity. From manufacturability through validation, we support solutions that safeguard your product and your reputation.

Introduction

What Is Packaging Injection Molding?

Packaging injection molding produces closures, caps, fitments, spouts, lids, containers and dispensing features that protect product integrity while enhancing consumer experience and brand appeal for a wide range of consumer packaged goods. Hoffer applies advanced injection molding technologies including multi-shot, high-cavitation and automated systems to deliver precision, consistency and scalability across global packaging programs.

Why it Matters

Packaging is both functional and emotional. It safeguards your product while creating the consumer’s first brand impression. Packaging must be leak-tight, user-friendly, safe and sustainable at volumes that meet global demand. Hoffer understands that every closure or fitment represents a brand promise. Our engineering and manufacturability expertise help customers bring validated, production-ready designs to life while ensuring quality, performance and sustainability.

Capabilities for Packaging Programs

Hoffer brings more than seven decades of experience in precision injection molding for food, beverage and consumer packaging. Our fully integrated platform delivers speed, reliability and quality at scale. In addition to custom-engineered components, Hoffer’s Lok™ family of closures provides proven, high-performance solutions for both rigid and flexible packaging applications.

Materials & Compliance

Hoffer manufactures a wide range of resins for packaging applications including polypropylene (PP), polyethylene (PE), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), thermoplastic elastomer (TPE), thermoplastic polyurethane (TPU) and other specialty grades validated for performance and quality.

Material selection is guided by:

- Chemical resistance, clarity, toughness and shelf-life stability.

- Food-contact and regulatory compliance where required.

- Controlled additives and colorants to ensure consistent brand presentation.

Design for Consumer Experience

Through close collaboration with customers and suppliers, Hoffer makes packaging concepts manufacturable, functional and scalable. Our engineering experts identify the right components and materials for each unique application, from fully custom closures to Hoffer’s proven Lok product lines, delivering designs that perform reliably, delight consumers and uphold brand integrity.

Quality, Sanitation & Traceability

Hoffer is ISO 9001:2015, SQF and MedAccred™ certified, delivering the quality assurance and manufacturing discipline customers rely on for safe, consistent, brand-protective packaging. Our proactive validation and documentation practices give customers peace of mind knowing every part is produced with precision, care and accountability.

Sustainability by Design

We view sustainability as a shared commitment with every customer. By combining responsible manufacturing with hands-on engineering support, we help brands achieve performance, protect products and deliver on their sustainability promises.

Typical Packaging Applications

With deep expertise in injection-molded packaging, Hoffer manufactures precision closures, fitments and components that balance functionality, safety and brand appeal. Serving global food, beverage and consumer brands, our solutions perform reliably across both rigid and flexible formats in high-speed filling, sealing and end-use environments.

- Closures and caps: Flat caps, flip-tops, child-resistant closures (CRC), tamper-evident (TE) designs and linerless sealing systems.

- Spouts and fitments: Pouch fitments, pour spouts and dispensing valves.

- Lids and overcaps: Snap-fit, tamper-evident and windowed lids.

- Dispensing systems: Flow restrictors, adapters, nozzles and pump interfaces.

- Containers: Custom injection molded rigid or semi-flexible containers.

How We Engage

Collaboration is at the core of every partnership with Hoffer. From early design through high-volume production, our team works side-by-side with customers to bring precision, reliability and efficiency to every packaging system. With more than seven decades of injection molding experience and a deep understanding of closures and fitments, we help brands move from concept to launch with confidence – because there’s a part of us in every piece.

FAQs: Packaging Injection Molding

Packaging injection molding is the precision manufacturing process Hoffer Plastics uses to manufacture closures, lids, spouts and fitments for both flexible and rigid packaging. Through controlled molding environments, advanced tooling and automated inspection capabilities, Hoffer ensures every component delivers reliable sealing, durability and food-safe performance.

Design for Manufacturability (DFM) is important in packaging injection molding because it ensures every component can be manufactured efficiently, consistently and to exacting standards. Hoffer’s engineering team collaborates early with customers to optimize geometry, tolerances and materials, resulting in reliable sealing, reduced risk and faster time to market.

Hoffer prevents leaks in injection-molded packaging through rigorous quality systems and validated processes. Operating under ISO 9001:2015 and SQF certification, we apply scientific injection molding, seal geometry optimization and in-line leak testing to verify that every component performs as intended and give consumers peace of mind.

Hoffer uses a range of materials for packaging applications, including PP, PE, PET/PBT, ABS, PC, TPE/TPU and PCR- or bio-based materials. These materials are validated to meet performance, compliance and sustainability needs.

Yes. Hoffer can handle high-volume and global packaging production through automated injection molding systems designed for continuous, high-volume manufacturing. Preventative tooling maintenance and process monitoring ensure consistent quality yields across millions of cycles, exceeding industry averages for uptime and tool life.

Yes. Hoffer supports sustainability goals by integrating environmental responsibility into every stage of manufacturing, from material selection and lightweighting to energy-efficient operations and closed-loop water systems. We help customers adopt recyclable, PCR and mono-material solutions that reduce environmental impact while maintaining performance and brand integrity.

Why Hoffer Plastics for Packaging

For more than 70 years, Hoffer Plastics has helped global brands bring their packaging ideas to life, from breakthrough dispensing systems to precision-engineered closures trusted by millions of consumers every day. Family owned and built on the values of family, integrity, service and trust, Hoffer combines deep engineering expertise with state-of-the-art manufacturing to deliver quality you can count on.

- Seven decades of proven packaging expertise through Lok closures and custom components.

- Engineering excellence that transforms packaging concepts into scalable, high-performance solutions.

- Operational excellence through automation, scientific injection molding principles and a focus on quality.

- Sustainability leadership that reduces waste and energy consumption.

- Full lifecycle partnerships through preventative maintenance, proactive communication and strong customer service and support.

Ready to launch or transfer a packaging program?

Share CAD, target resin, sealing and dispensing specs and cosmetic goals. We’ll build a plan to scale quickly and reliably.

"*" indicates required fields