ABOUT US

Since 1953, Hoffer Plastics Has Been a Trusted Partner in Custom Injection Molding

Our family-owned roots provide a foundation of commitment and craftsmanship that define every part we produce. With over 350 team members operating out of a 365,000-square-foot facility and delivering more than 3 billion parts annually, we combine manufacturing innovation – like our pioneering Lok™ family of closures – and an unwavering 99.45% on‑time delivery record to meet our customers’ needs.

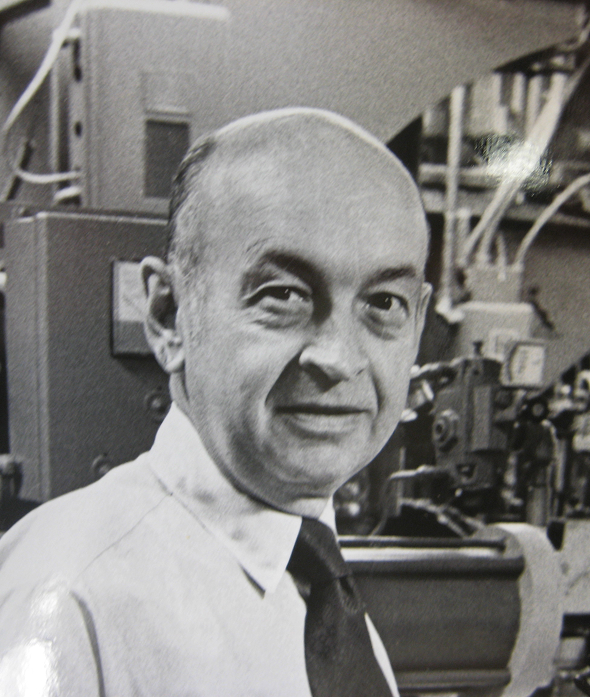

Founder’s Intent

Guided by our core values of family, integrity, service, and trust – and award‑winning recognition for sustainability and operational excellence – we’re dedicated to building long‑term relationships and paying forward the legacy of service that started it all.

Manufacture plastic parts that positively impact lives.

Live our values by following our standards and policies.

Deliver quality parts to our customers on-time.

Core Values

Family, Integrity, Service and Trust

Expertise

A Trusted Global Provider of Precision Injection Molding

Hoffer Plastics has been a trusted global provider of precision injection molding – partnering with businesses from local startups to Fortune 100 companies across diverse markets from baby food packaging to automotive parts. Our advanced capabilities – including gas-assisted molding, MuCell lightweighting, two-shot and co-injection molding, insert molding, post-mold decoration and metal-to-plastic conversions – are powered by world-class facilities, state-of-the-art prototyping and engineering expertise. We support customers from concept through delivery, consistently delivering tight-tolerance, high-quality parts on-time while leading the way in sustainability and community-driven manufacturing.

Industries We Serve

Hoffer Plastics delivers expert injection molding across a diverse range of industries – spanning food and beverage, lawn and garden, home care, consumer products, automotive, personal care and medical and pharma – by delivering custom solutions built for performance and precision. At the forefront of this innovation is our Lok family of caps and spouts, engineered for both rigid and flexible packaging. With standout features like superior tamper evidence, hermetic seal integrity, choke-safe design and compatibility with PP/PE recycle‑ready films, these closures excel across markets – from condiment pouches to pharmaceutical dispensers – while supporting sustainability and seamless filling operations.